Home

Home

Back

Back

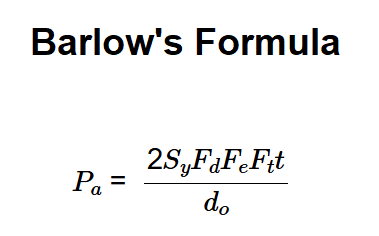

Definition: This calculator computes the maximum allowable design pressure (\( P_a \)) for a pipe using Barlow's formula: \( P_a = 2 S_y F_d F_e F_t t / d_o \), where \( S_y \) is yield strength, \( F_d \) is the design factor, \( F_e \) is the longitudinal joint factor, \( F_t \) is the temperature derating factor, \( t \) is wall thickness, and \( d_o \) is the outside diameter.

Purpose: It helps engineers and designers determine the safe operating pressure for pipelines, ensuring structural integrity and compliance with industry standards in liquid and gas pipeline applications.

Calculations are based on Barlow's formula:

Unit Conversions:

| Category | Unit | Conversion to SI Unit |

|---|---|---|

| Pressure | psi (Pounds per square inch) | 1 psi = 6894.76 Pa |

| Pa (Pascals) | 1 Pa | |

| bar | 1 bar = 100,000 Pa | |

| kPa (Kilopascals) | 1 kPa = 1000 Pa | |

| MPa (Megapascals) | 1 MPa = 1,000,000 Pa | |

| at (Technical atmospheres) | 1 at = 98,066.5 Pa | |

| atm (Standard atmospheres) | 1 atm = 101,325 Pa | |

| Torr | 1 Torr = 133.322 Pa | |

| hPa (Hectopascals) | 1 hPa = 100 Pa | |

| inHg (Inches of mercury) | 1 inHg = 3386.39 Pa | |

| Length (Wall Thickness, Outside Diameter) | in (Inches) | 1 in |

| mm (Millimeters) | 1 mm = 0.0393701 in |

Details: Accurate calculation of maximum allowable pressure is critical for ensuring pipeline safety, preventing failures, and complying with engineering standards for liquid and gas pipelines.

Tips: Enter Yield Strength (psi, Pa, kPa, MPa, bar), Design Factor (select pipeline type or custom value), Longitudinal Joint Factor, Temperature Derating Factor, Wall Thickness (in, mm), and Outside Diameter (in, mm). Results include maximum allowable pressure in multiple units (psi, Pa, bar, kPa, MPa, at, atm, Torr, hPa, inHg).

Notes: The design factor (\( F_d \)) depends on the pipeline type (liquid or gas class). Typical values are provided and automatically filled when selected. All factors (\( F_d \), \( F_e \), \( F_t \)) should be between 0 and 1. Wall thickness and outside diameter must be positive values.